DIY brandstofpolijstsysteem

Transcript from video

We spent nearly five years in the pacific and we were buying diesel from some fairly small roadside garages and so on so we were using jerry cans and our routine would be to buy the diesel leave it a stand for a day have a good look inside and then use a siphon tube which only went to about an inch above the bottom of the tank so any crud that was in the bottom wouldn’t get sucked up into the main tank when we transferred it and it was surprising how much crud we did find but now here back in the uk even with supposedly clean diesel there’s an increasing risk of microbial growth within diesel it’s called diesel bug and it’s where water and diesel mix and it’s not helped by the fact that now diesel has a degree of biofuel added to it and that’s increasing the issue so we’ve decided to try and find a way of cleaning our diesel on a regular basis to remove the risk of diesel bug clogging our engine’s filters mourning’s fuel tank is mounted below the floor so there’s only access from the very top section here but there is a small access port here and this allows us to use a copper tube to dip down right to the very base of the tank and that’s going to be the basis of the fuel polishing system that we’re putting together.

The concept of the fuel polisher is to have a constant flow from the bottom of the tank through the filter and water separator and back to the top of the tank. I’d originally thought to actually put this in a hard wired effectively into the in-feed and outfeed lines for the engine but that looked fairly complicated and i changed plans and decided to make this a completely portable unit i think this gives us probably three key advantages first of all it allows me to clean the tanks and we have two on board secondly it allows us to transfer and clean fuel from jerry cans without like messing around with siphon tubes and finally it’ll be a lot easier to fit well the big box of components from asap supplies has arrived time to unpack it and see if i’ve got all the right bit.

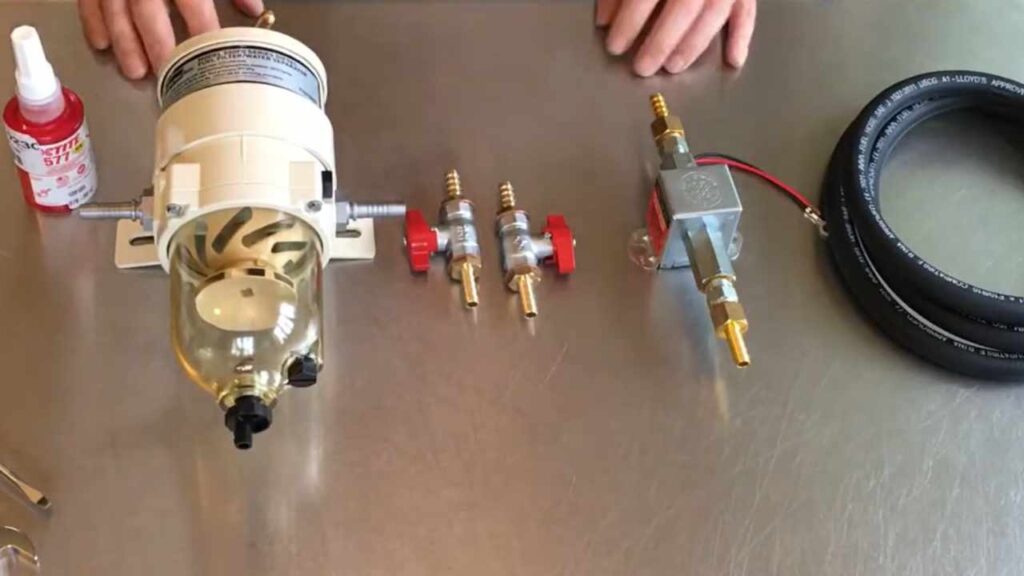

The heart of this system is a Racor 500 filter it uses turbine technology to spin out any water and debris to be collected in a polycarbonate bowl then there’s a second 10 micron filter to remove any remaining water droplets and debris. A Facet 12 volt pump will do all the hard work and of course there are a whole bunch of connectors barbs and valves for the pipework so that’s the mechanical connections completed. The red stuff by the way is Loctite 577 it’s a medium strength thread locker to help stop any leaks of diesel but I have used copper washers where i can on these valves as well so mechanical bits done ready to set together uh but i now need a 12 volt power supply for the pump. It only draws about one and a half to two amps so it doesn’t need a big set of cables and i already have on the boat uh an old but a cable with a 12 volt uh power supply uh plug um so in theory i could just use that on on switched and just plug it straight in but i am an engineer so i wanted a slightly more uh tidy solution so within the system. I’m going to have a control box uh 12 volt switch and uh going slightly over the top here perhaps a digital hour counter and the idea of this is it’ll allow me to run the fuel polishing system keep an eye on how long it’s been running the pump takes capacity is about 120 liters an hour so i’ll know roughly how many liters i’ve pumped through the system and it also gives me a running total on how long the

(04:19) filter in this record will last so next job is to drill this fit it and then i need to mount it all on a board and put it into a case [Music] [Music] well now the cat’s got out of the way you get a better idea of what we’re doing so this dimension here is the size of the case that this is going to go into at least i think it is unfortunately i bought second hand one on ebay and it seems at the moment that the couriers lost it so i’m not going to cut the board and mount all this until i know i’ve actually got the right case

(05:12) but broadly speaking the concept is pretty clear now so we’ve got infeed here we’re going to put some copper tube in here about a meter length and that’ll dip into the bottom of the fuel tank through the filter it then sucks through the pump that’s the most efficient way to have the pump on the suction side and then the outfeed goes through another pipe another bit of copper tube back into the tank so that’ll all get mounted of course we’ve got our control box with switch and the counter that’ll need to be wired up

(05:43) but kind of until i get the correct box to put it all in i probably can’t go much further but it gives you an idea of where we’re at to so far well the bad news is that the courier did in fact lose the case but the good news is the vendor managed to claim off them and gave me my money back and i found a company selling these chinese-made waterproof cases uh 50 pounds including postage so uh it’s slightly bigger than i wanted but actually it’s made it easy to fit so what we have with the case is everything mounted on a backboard

(06:19) and ready to go [Music] [Applause] so i’m very pleased it all runs and there were no leaks which is great but um we really need to test it and i’m going to do something i’ve never done before which is to pour some water into my diesel i’ve added a bit of colour to it a bit of dye just to see what it does [Laughter]

(07:36) two three three three well you saw in the slo-mo the turbine system just sort of spun the water out and dropped it straight to the bottom of the bowl so it only took about maybe 15 seconds and there’s the line this is the water at the bottom and there’s the diesel above so we have to do now is open the drain and drain it out so i am super impressed with that really pleased i was able to hoover up everything from the bottom of the tank

(08:40) could see no black water left in there at all and it’s done what i wanted it to do so i think what i’ve done it’s got something that’s really going to be a good addition to the boat i can’t wait get to get down to the boat to hoover out the bottom of the tanks and see what muck we find in them but of course it didn’t come cheap this bit of kit um well the the raker itself about 230 pounds the the pump about just under 70.

(09:07) so with all the sort of uh hardware there’s about 340 350 pounds worth of equipment there i use a company called asap supplies they actually give me a 5 discount because i’m a member of the cruising association the electric’s about 20 pounds from iris components bits and pieces are obviously my time so around about 400 pounds including the 50 pound case but this year we had our engine falter and die because its main filter blocked as we were motoring down the irish sea thankfully very calm weather but i had to change the primary filter at sea

(09:43) which isn’t a lot of fun so i’m really hoping this is going to be a case of giving me confidence that i start the any any trip with really clean diesel in the tanks.

Click on image to view video

Zoekopdracht

Ondersteuningsvideo's

Gerelateerde producten

Racor 500FG10MTC (Metric Ports) Fuel Water Separator

Racor 500FG2430MTC (with 24V Heater, Metric ports) Fuel Water Separator

Racor 500FG2 Brandstofwaterafscheider-500FG

Racor 500FG242 (with 24V Heater) Fuel Water Separator

Racor 500FG2430 (with 24V Heater) Fuel Water Separator

Racor 500FG10 Brandstofwaterafscheider-500FG

Racor 500FG30 Fuel Water Separator

Racor RK15405 Komkit 500FG

Racor RK1530101 Komkit 500FGM

Racor RK1544002 Verwarming-doorvoer 500FG-24V

Racor RK30476 Afvoerset 500FG

Racor RK15035 Komringset 500FG

Racor RK15078 Dekselkit 500FG

Racor RK11780 Afvoerset 500FG